Compound Steam Locomotive

This summer, we rode the 1880 Train, from Keystone SD to Hill City SD, and back. Easily worth the price of tickets, lots of fun, and you get to see South Dakota’s Black Hills in a way you won’t otherwise.

I’ve taken a ride on Durango and Silverton narrow gauge railroad in Colorado, probably 30 years ago. After reading How Steam Locomotives Really Work, the 1880 Train was a different experience.

I was specifically looking at the cylinders, trying to pick out the valves, and looking at the valve gear.

As near as I can tell, the trains are mostly pulled by locomotive No. 110 a 2-6+6-2T Mallet compound locomotive. No. 110 pulled the train I rode.

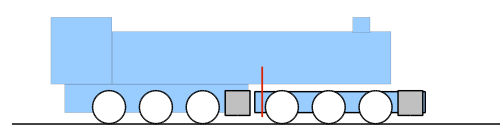

Here’s a conceptual diagram of a Mallet locomotive:

The vertical red line is where the front bogie pivots relative the the rest of the locomotive. Cylinders are grey.

And here’s the best image I took of the right side of No. 110, which is embarrassingly bad:

I marked where I think No. 110’s articulation pivot is, and outlined front and back cylinders in grey. This mostly matches the conceptual diagram above.

A “compound” locomotive expands its steam twice, once in a smaller diameter piston, and a second time in a larger diameter piston. The idea is to get more work out of the steam. A Mallet locomotive supposedly expands the steam through high pressure cylinders in the back into a “lower pressure receiver”. The front pistons are driven by steam from this receiver.

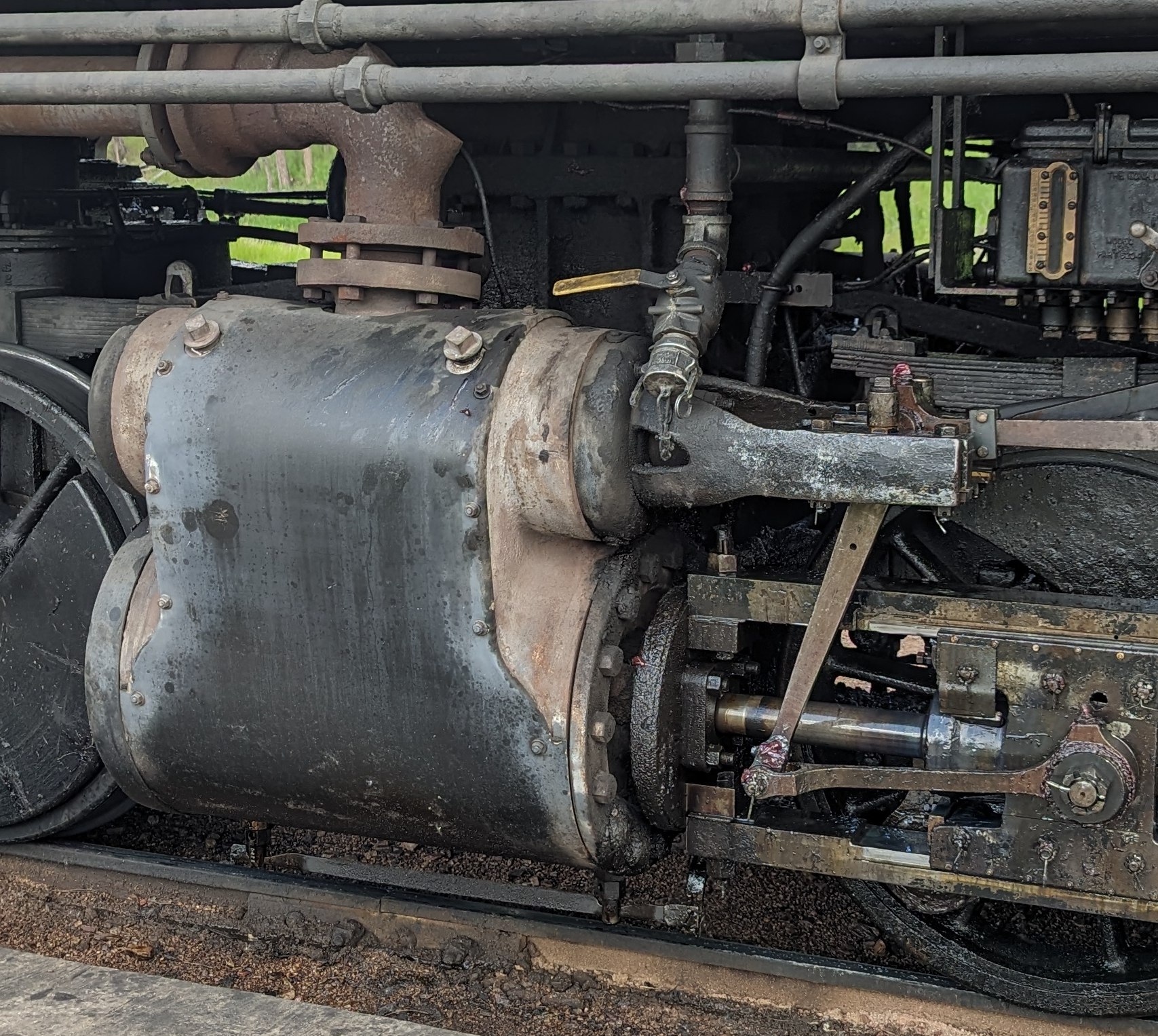

There’s the front (low pressure, bigger diameter) cylinder (and valve on top) in a closeup. I believe the black pipe behind the locomotive’s frame leads the steam exhausted from the cylinder into the blastpipe.

Above, a closeup of the rear (high pressure, smaller diameter) cylinder. I think the double-flanged rusty pipe routes boiler steam into the valves. The Wikipedia article on compound locomotives says that low pressure cylinder is customarily 2.25 times the volume of the high pressure cylinder. Just by eye, I’d say these two cylinders are about that ratio.

I can’t figure out where the lower pressure steam exits the rear cylinder, and gets routed to the front cylinder. Given that the front pistons are on a pivoting bogie, the steam pipes getting to the front cylinders must have flexible joints somewhere along them.

I took a picture of the cab, because I could see the pressure gauge:

I make out the pressure gauge as reading 165 pounds per square inch. There were sight glasses indicating water level in the boiler, too.

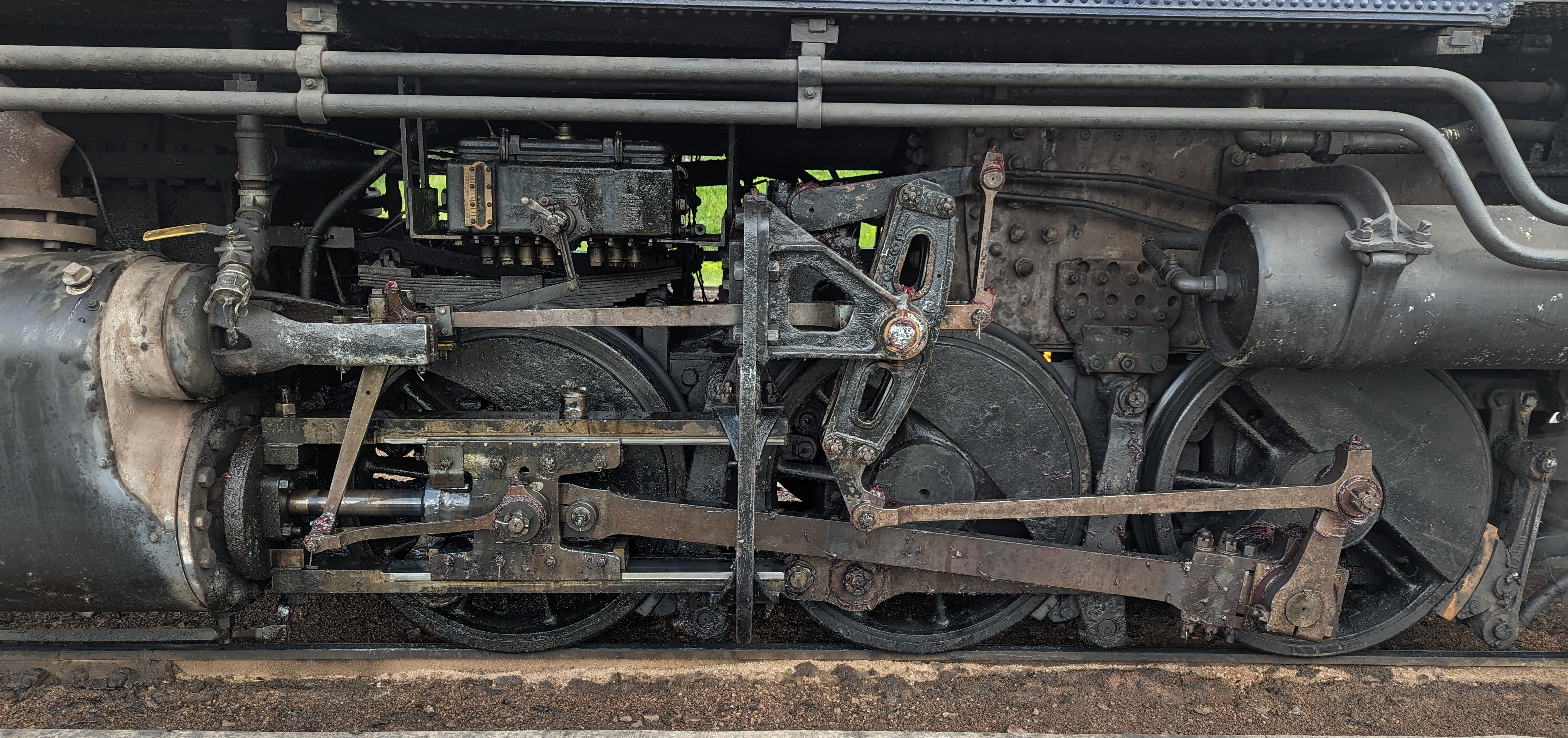

Here’s the left side, rear, high pressure, cylinder’s valve gear. I think this is Walschaerts valve gear. No. 110 was designed in 1928. That’s some fine mechanism design if you ask me.

Thermodynamics never sold a single locomotive

Attributed to Oliver Bulleid, the last of the British steam locomotive giants.

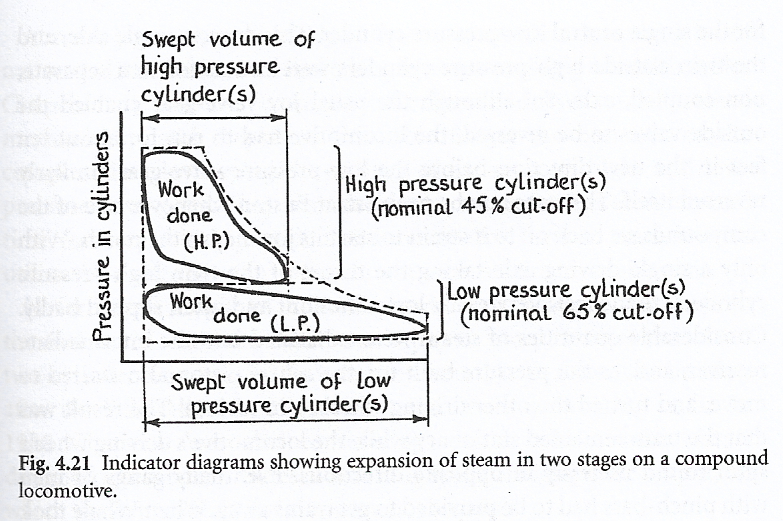

That’s an indicator diagram of compound expansion steam cylinders from the book How Steam Locomotives Really Work. The book doesn’t describe these in great detail, but it sounds like British railways had some apparatus they would attach to a locomotive’s cylinder that graphed pressure in the cylinder against piston stroke. The diagram above has an X-axis of “swept volume”, but that’s just stroke x piston area, a way of normalizing the two sub-diagram’s X-axes.

Since the cylinders are of different diameters, but have the same stroke, a comparison of higher and lower pressure cylinder’s pressure vs stroke diagrams would be less than intuitive.

The “work done” area in the diagram would have units of pressure x volume, (pounds/in2) x in3 = inch-pounds, conveniently the units of work or energy.

Implications of running restored steam locomotives

Steam locomotives exploded every once in a while. I’m sure this was almost always attributed to crew error, but still… running a restored locomotive has some risks. I wonder what the Black Hills Central railroad does to ensure that No. 110’s boiler, steam-carrying pipes and cylinders are all good? They might X-ray everything periodically, and they must inspect for cracks, perhaps by penetrant dye. Everything is so astonishingly grimy (as evidenced in my images above) that inspecting for cracks would be awful.